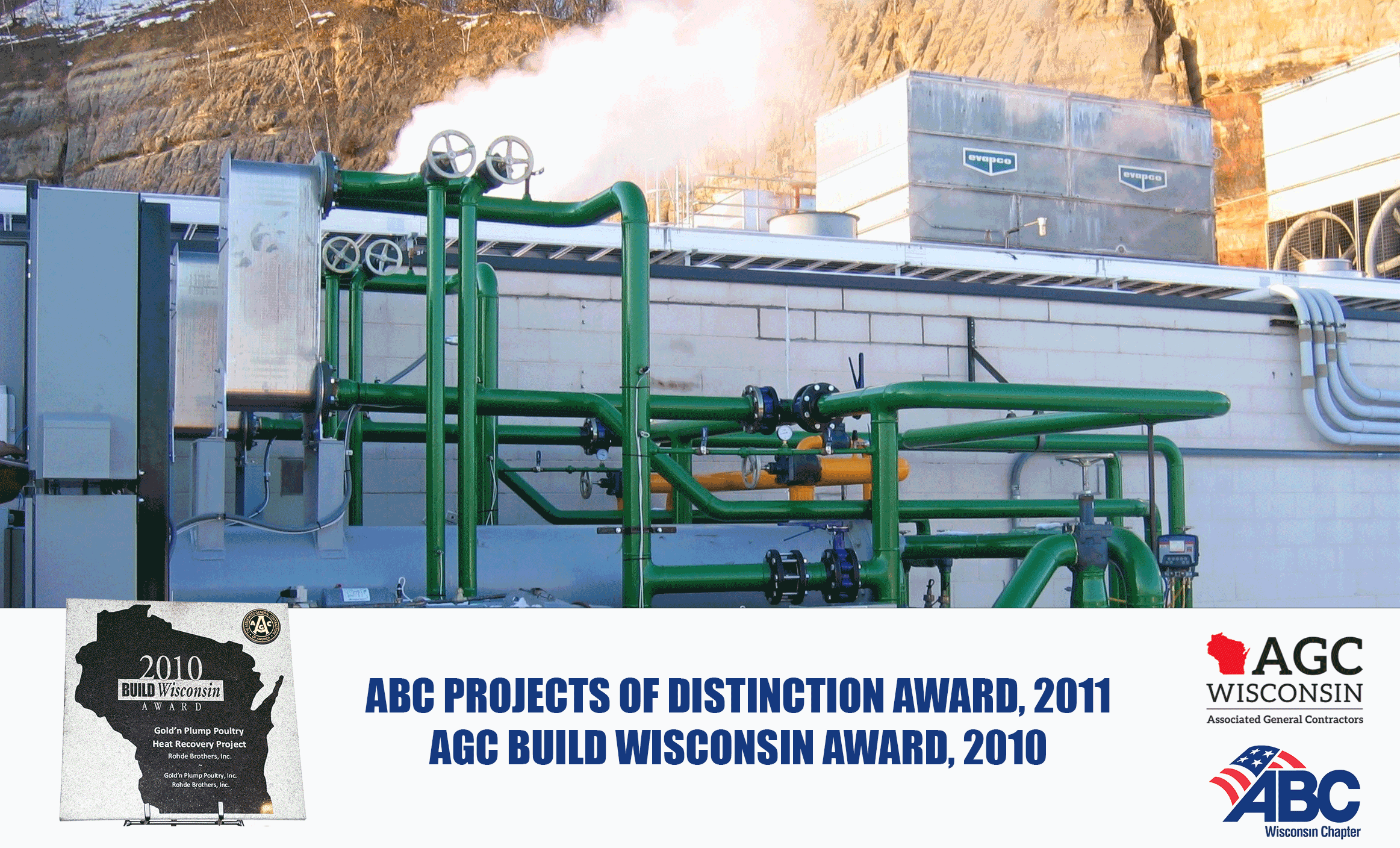

Waste Heat Recovery - Gold N Plump Poultry

“As we look forward to this cost savings over time we realized that we would have gone in the same expensive wasteful direction if we had not met with Rohde Brothers, Inc. The solution that they provided in two of our locations is exactly what we’d hoped for, and that is pretty challenging to come by in today’s business environment.”

Customized Solution:

-

A custom designed heat pump that is 8 times larger than what is traditionally available

-

Directly recovering heat from an ammonia refrigeration system

-

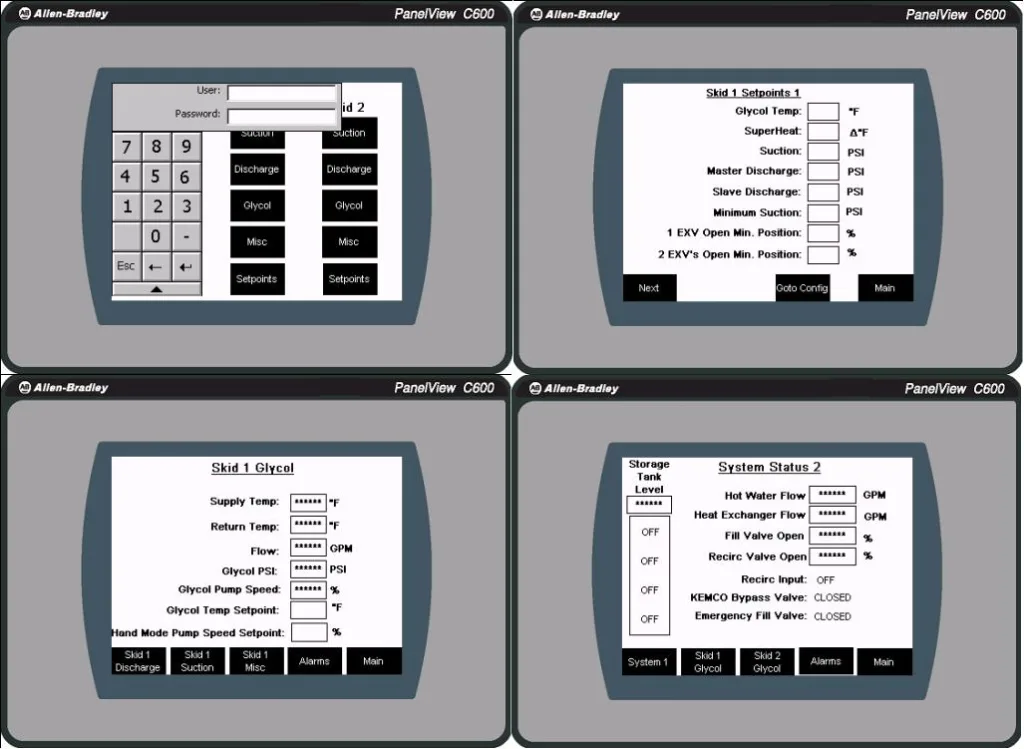

Integration of hot water heating system controls with the ammonia refrigeration controls

-

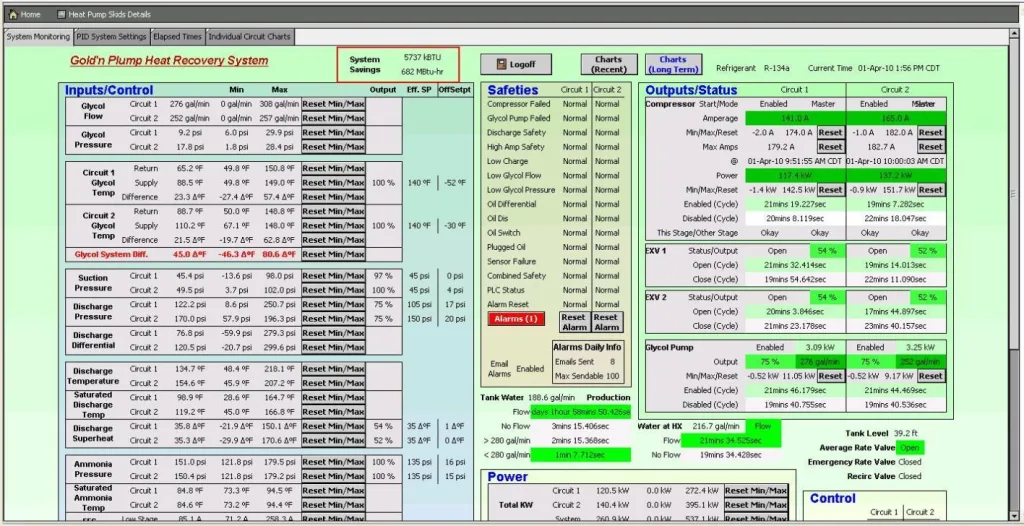

Remote monitoring and data collection

-

Rohde designed, engineered and implemented the system within 6 months, typically during scheduled plant shutdowns. Working closely with Gold’n Plump’s team, Rohde ensured integration of the new system with minimal disturbance to the existing facility and processes in place

-

Rohde engineers scaled an existing heat recovery design to accommodate the plant’s daily use of 1,000,000 gallons of 140°F water for production and sanitation

-

This is the largest heat pump heat recovery unit in Wisconsin

-

Saved Gold’n Plump $178,000 per year in energy costs