Rohde Brothers, Inc Expands Fabrication Space

When Rohde Brothers, Inc. needed to expand it’s fabrication facility the leadership team decided to add some state-of-the-art features in order to innovate and save energy and cost at the same time.

The new 11,000 sq foot space includes dual 20 ton cranes, dedicated stainless steel manufacturing space, an equipment test cell, and a host of energy efficiency features:

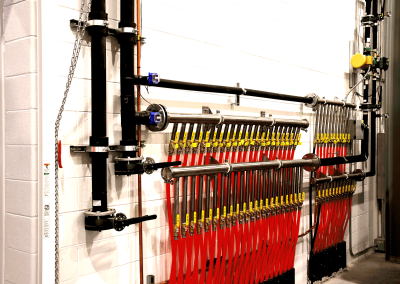

This project was designed in our facility using BIM/CAD. The project included a horizontal field type geothermal system, a boiler system to assist the geothermal, an ice bank system and dual chiller compressors to “cool” the space in the warmer months. The energy efficiency components of the system will likely save Rohde Brothers 36% on it’s heating and cooling costs annually.

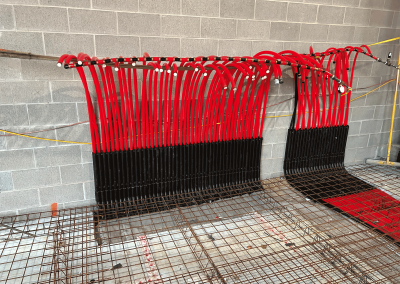

In addition, a snow melt system was placed at the north end of the structure under the apron to prevent snow and ice accumulation. This system actually is safer for employees, uses heat that is already in the system, and removes the need to plow snow in that area, reducing CO2 emmisions.

Customized Solution:

- 3D modeling used to facilitate an aggressive construction schedule, and to coordinate the complex mechanical and electrical system installation.

- Waste heat from the chillers, hydraulic power unit and air compressors is utilized to provide heating and cooling.

- A horizontal ground based geothermal system provides constant tempreture to heat/cool based on season.

- Major equipment:

- Dual KBX400 Boilers providing any needed heat for the snow melt or building heat.

- 400 Gallon Hot Glycol storage tank insulated to maintain 108 degrees.

- Dual 400 MBH Condensing units built at Rohde Brothers, Inc.

- Gas Fired 300,000BTU unit heater.

- Dual Rupp economizer exhaust units.

- 15 Ton Ice Bank system

- 5690CFM Fan Coil Unit